Unlocking Precision: Key Techniques In Machining & Engineering

Are you intrigued by the intricate world where raw materials transform into meticulously crafted components? Precision machining, an essential pillar of modern manufacturing, is the art and science of shaping materials with unparalleled accuracy.

This field encompasses a diverse array of techniques, each meticulously employed to sculpt materials into precise parts. From the aerospace industry to the medical field, precision machining is the cornerstone of countless innovations, enabling the creation of products that meet exacting standards of performance and reliability. Let's delve into some key methods and the companies that are shaping the future.

| Feature | Details | | :-------------------------- | :---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- | | Company Name | Precision Techniques, Inc. | | Business Type | Domestic Business Corporation | | Date of Filing | January 27, 1988 | | Filing Status | Active | | File Number | 1230541 | | Registered Agent | Precision Techniques, Inc. | | Registered Address | 1169 East 156th St, Bronx, NY 10474 | | Industry Expertise | High precision machined components and assemblies | | Industries Served | Aerospace, Automotive, Computer, Data Storage, Dental, High Precision Research Components, Medical Devices, and Ordnance | | Years of Experience | Decades | | Reference Website | Example Website (Replace with an actual website) |

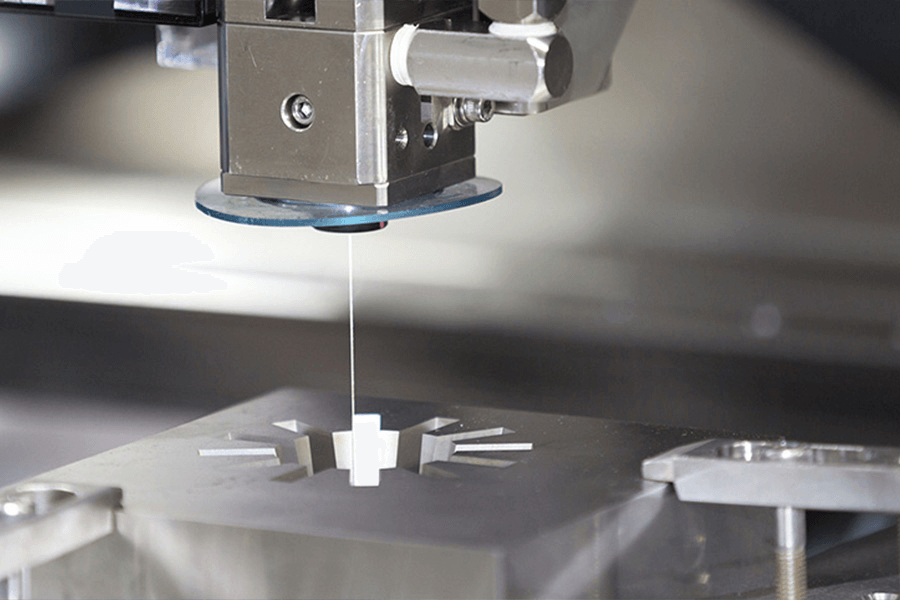

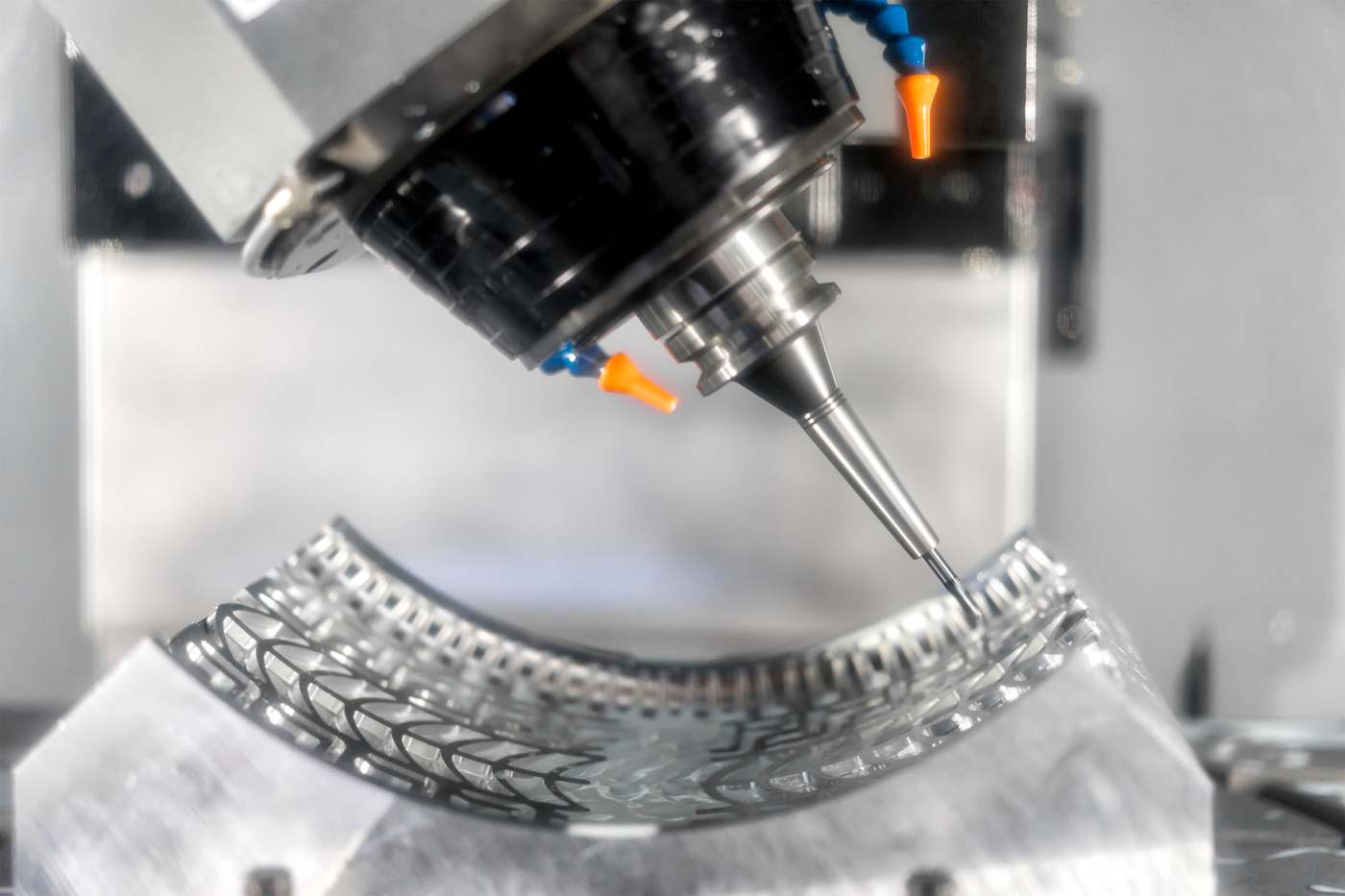

At its core, precision machining relies on the strategic removal of material from a workpiece. This process, often guided by sophisticated software and computer numerical control (CNC) equipment, is what allows for the creation of complex geometries and exacting tolerances. Techniques like cutting, drilling, milling, and grinding are instrumental in this process.

Cutting is a fundamental process, the initial act of shaping the raw material. This might involve separating a piece, creating an initial outline, or roughing out a shape. Drilling creates precise holes of various sizes. Milling uses rotating cutters to remove material, creating intricate shapes and features. Grinding, a finishing process, uses abrasive materials to achieve the highest levels of precision and surface finish.

The versatility of precision machining extends to the materials it can handle. From the strength of alloy steel and carbon steel to the corrosion resistance of stainless steel and the lightweight properties of aluminum and bronze, precision machining adapts to the demands of diverse applications. Further enhancements often involve heat treating and surface treating, ensuring that the final product possesses the desired mechanical properties and longevity.

The design phase is where the entire process begins. CAD (Computer-Aided Design) software allows engineers to create detailed 3D models of components, providing a virtual blueprint for the manufacturing process. It is here that the specifications are defined, and the path to precision is laid out. Following this, the selection of the right tools, the programming of the CNC machine, and the meticulous execution of the machining process are crucial.

Precision engineering also involves the body of knowledge, wisdom, and techniques used to design such a machine or instrument. Subdisciplines of precision engineering include precision machine design and optomechanical engineering. These techniques ensure that every component produced meets the highest standards of accuracy and reliability.

The principles of precision machining extend beyond individual components, playing a critical role in the broader context of manufacturing. It provides the concepts and tools necessary for engineers to create new precision machine designs. When combined with heat treating, surface treating, and quality inspections, these processes produce finished products that are ready for use in their intended applications.

The advancements in CNC precision machining have further refined the process. These advances have enhanced accuracy and simplified the manufacturing process, leading to greater efficiency and capabilities. This has enabled the creation of increasingly complex and miniaturized components, essential in industries such as electronics and medical devices.

The focus is on achieving optimal performance in precision engineering, and several advanced techniques are employed to achieve this goal. CAD software, precision cutting techniques, and CNC automation are all part of this approach.

In the realm of New York businesses, Precision Techniques, Inc., a domestic business corporation filed on January 27, 1988 (File number 1230541), stands as an example of the industrys commitment to quality. The registered business location is at 1169 East 156th St, Bronx, New York 10474. The DOS process contact is precision techniques, inc.

Another example of an organization in this field is Techniques LLC, which provides decades of experience in the manufacturing of high precision machined components and assemblies serving all industries, including aerospace, automotive, computer, data storage, dental, high precision research components, medical devices, and ordnance. Such firms underscore the importance of experience and innovation.

In the world of agriculture, precision farming (PA) and wireless sensor networks (WSN) are transforming traditional methods. PA uses specific sensors and software to ensure that farming practices become more efficient. A critical aspect of this study is a detailed discussion of image analysis and computer vision techniques applied to important precision farming tasks, with a particular focus on analysis and detection techniques for soil monitoring, stress detection, targeted spraying, yield estimation, and quality control. Precision agriculture takes into account innovative concepts to transform traditional farming methods. When traditional farming is integrated with advanced technology for agricultural practices, this approach can enhance efficiency, productivity, and sustainability.

The process of diamond cutting is another field which relies on the principles of precision. Mastery of diamond cutting requires precise techniques for unparalleled brilliance, unlocking dazzling sparkle and radiant shine. It is a delicate and nuanced process.

As with all types of machining, optimization is key. Now that you understand more about CNC profile cutting, lets go over some techniques you can use for optimization! Precision begins with the design phase.

In the deep learning community, increasingly large models are being developed, leading to rapidly growing computational costs and energy costs. Recently, a new trend has been arising, advocating that researchers should also report the energy efficiency besides their models performance in their papers. Previous research has shown that reduced precision can be helpful to improve energy.

From the manufacturing of components in aerospace and automotive to the creation of high precision research components, precision machining continues to evolve. Its a testament to human ingenuity, a blend of art and science, that transforms raw materials into the essential building blocks of our modern world.